Client

Carbon Group

Location

Ireland

Services

- MEP Services,

- Health & Safety,

- Process Engineering Services

Sectors

- Built Environment Design Services,

- Industrial

Sub-sector

- Industrial Food & Beverage

Period

01/01/2023

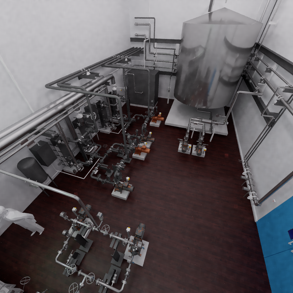

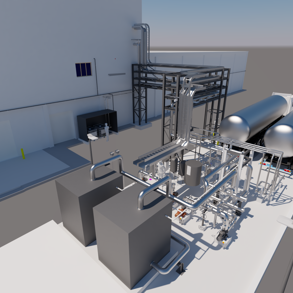

RED developed a full detailed design of new Food Ingredients manufacturing facility to replace a derelict Grain Store on site. Design included 2 x 30 m^3 mixing vessel with heating/cooling capabilities.

A Powder handling unit to transfer powders from 25 kg bags to 1,000 Kg FIBCs which can then be transferred to mixing vessels via a hoist, system includes a weigh scales to allow for partial filling. Boiler and Chillers to provide temperature control. New GMP standard finish clean room for GMP Powder Handling activities. System will provide ability to charge contents of mixing vessels to IBCs or to Liquid Tankers via a Tanker Loading Bay.

TALK ABOUT THIS PROJECT

Unlock the potential of your engineering projects with our expert consultation services. Our team of knowledgeable professionals is ready to provide guidance and innovative solutions tailored to your specific needs. Contact us today to discuss how we can help you achieve your goals.

Get in touchPROJECT SUMMARY

The project involves the detailed design of a new Food Ingredients Production (FIP) facility on site. The scope includes the design of two independent multi-product mixers, each with a capacity of 30,000L. The design also encompasses dedicated facilities for FIBC loading, Clean-In-Place (CIP) systems, heating/cooling systems, additional de-ionized water (DIWater) generation capacity, and all necessary services and controls.

Reduced cycle time

New system will reduce cycle time for a typical batch 10 hours

Operator and Powders

New system will significantly reduce Operator exposure to potentially Hazardous Powders by creating a physical barrier between Operator and Powders.

Improved ergonomics

New system will allow for significantly larger batches to be manufactured thus reducing number of Operator touch points for each batch, helping to reduce personnel and material flows and improve ergonomics.