14 Apr 2025

10 minutes to read

Sustainability in Engineering: Transforming Data Centres into Eco-Friendly Hubs

Many world cultures deeply appreciate old objects; either for craftsmanship, sentiment, historical or spiritual significance or simply for their beauty alone. Italian love of renaissance and Romanesque; Middle Eastern admiration of calligraphy and carpets; gold and handwoven textiles in central Asia and the English obsession with anything old (including a garden hoe). The most unique of all is probably the Japanese respect for the beauty of aging with all its imperfections.

Figure 1. A fine example of Japanese kintsugi, in which objects obtain a spirit when carrying signs of damage, imperfection and repair [1].

The tech sector has always embraced change, and the economic notion of creative destruction. Out with the old, innovate and disrupt to bring in the new. The industry is however facing a watershed moment: many of its first generation DCs are now due for refurbishment, and its new facilities need to accommodate energy and water intensive AI infrastructure while simultaneously reducing resource use in line with a range of widely accepted decarbonisation plans. As well as water, operational energy and refrigerants, embodied Carbon and circularity are now under scrutiny in more stringent regulatory environments. One example is the UK, in which (for a shell and core DC), the UK Net Zero Carbon Building Standard currently proposes an embodied CO2 footprint of 705 kgCO2e/m2 in 2026, which is then progressively reduced to arrive at 45 kgCO2e/m2 in 2050.

One area with huge potential to reduce project embodied Carbon is structural steel. Most DCs are steel framed structures, and even those with a masonry envelope are likely to have substantial steel deployment. Conventional steel production is very Carbon and energy intensive, its mining, grinding, smelting and casting consume 7%-9% of the world primary energy; leading to 9% of global CO2 emissions [1]. Steel is therefore a perfect candidate to be examined closely.

Steel reclamation, developing a roadmap

Addressing environmental impact of steel production was the motivation behind Pinnacle structural steel reuse roadmap. Structural steel sections are robust, meticulously bolted together and often experience a fraction of loads they are designed for. As such most remain in excellent condition and are a perfect candidate for reclamation. However, reusing them is not a straight forward process; availability, traceability, recertification, refabrication costs, perception of integrity by client, all can collude to defeat a reclamation programme.

Pinnacle Consulting Engineers solution was to create a detailed methodology so that clear principles could be followed to guide the general contractor and by extent the demo contractor in re-claiming steel. A streamlined process de-risks adopting the reclamation process for client, potentially saves cost, integrates circularity into the design from the outset and produces a more resource efficient building. The process facilitates the reuse of steel in any country that adopts the Eurocode suite of standards. So long as the steelwork is erected post 1970s, hasn’t suffered significant strain or fatigue (i.e. as in bridges) or exposure to fire or corrosion section loss, a reuse assessment in line with SCI publication P427 [3] can be performed. The adoption of this approach is highly recommended in all projects to enable early engagement with the client and the supply chain to achieve net zero targets by 2050. It is worth noting that re-claimed steel is but one dimension of the multi-faceted approach outlined in the following publication.

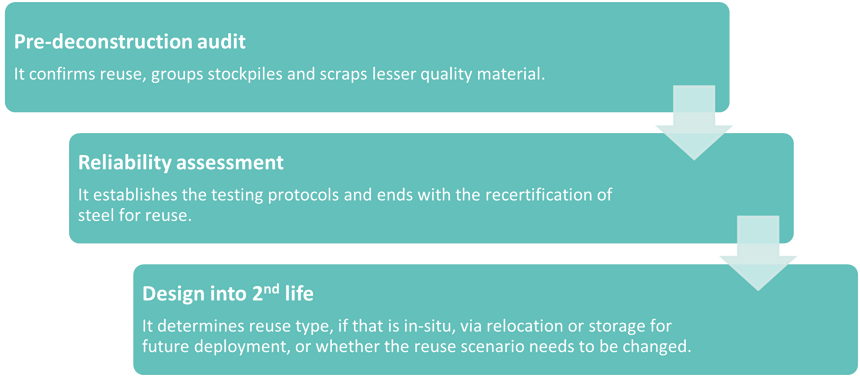

Figure 2. Pinnacle Consulting Engineers’ Net Zero from Stage Zero method statement.

Fig. 3 outlines a simplified version of Pinnacle’s assessment through which the design team can reach clarity swiftly. Reclamation triggers a more meticulous (and costly) demolition, requires grouping of reclaimed steel for different testing regimes, sometimes assumptions also need to be made. Therefore a robust roadmap clearly outlines how to group the stockpile, which test to undertake and how to evidence the suitability of reclaimed steel. Testing are generally limited to none-destructive methods (among which are ultrasonic, magnetic particle or radiographic testing), while statistical testing might also be necessary in which one destructive test is performed on a member of each group. Destructive testing is triggered where steel needs to be used in consequence class 3 buildings or its origin source is unreliable.

Enhancing steel reclamation with BIM: While current economic and legislative forces may not allow steel reclamation to become mainstream, BIM technologies can change this trend by providing certainty on material properties, traceability and provenance; potentially also eliminating the need for testing.

It is vital that the results of all tests, actions undertaken and certification obtained are documented diligently. Reclamation process can be subjected to an independent external audit. The end product would be for all reclaimed steel elements to have a certification label (QR Code) associated with them which provides full details of the section. These can then form part of a stockpile for steel fabricators who enable circularity of steel by making reclaimed products part of the supply chain.

Figure 3. An abbreviated diagrammatic process of Pinnacle's steel reuse assessment procedure. The none-abbreviated version contains a decision tree with multiple feedback loops at each stage. ![]()

Pinnacle Structural consultants and RED engineering Design have been able to work with European DC clients to apply this assessment and reclaim as much of the structural steel as possible from an existing structure to validate for reuse in the replacement building. The re-claimed steel option in combination with the greener steel material typology will help further enhance the opportunities to achieve client’s net zero ambition by 2050.

Impact on embodied carbon

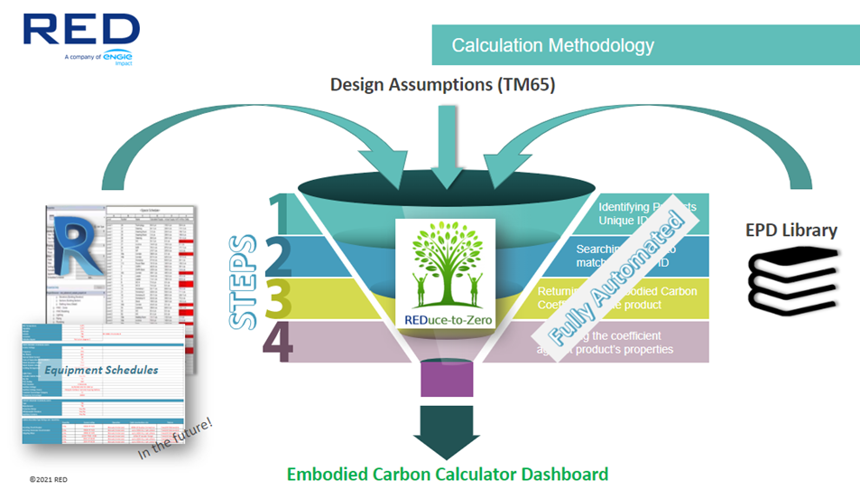

It is possible – for any given design – to quantify the Carbon savings that steel reclamation achieves via a WLCA study. RED Engineering Design uses some of the most advanced tools in the market to perform comparative analysis and identify ways to reduce project Carbon footprint. To achieve this, BIM data, Quantity Surveyor’s volumes/quantity, OneClick LCA platform and RED’s own inhouse tool (REDUCE-2-Zero) are used to merge project data seamlessly. The real value of most WLCA tools lie in the extend and accuracy of their database, and to that end RED has an ongoing data compilation process. Together with its unique DC design insights generated via research, manufacturer consultations and RED’s unique wealth of MEP product information, RED has performed many WLCA for DC projects at all RIBA stages.

[1] Class 3 is the last of the three building class type in which failure has high consequences.

Figure 4. A visual summary of REDuce-to-Zero calculation methodology. Where appropriate CIBSE TM65 calculations are used to ensure new products are modelled in accordance with best practice.. ![]()

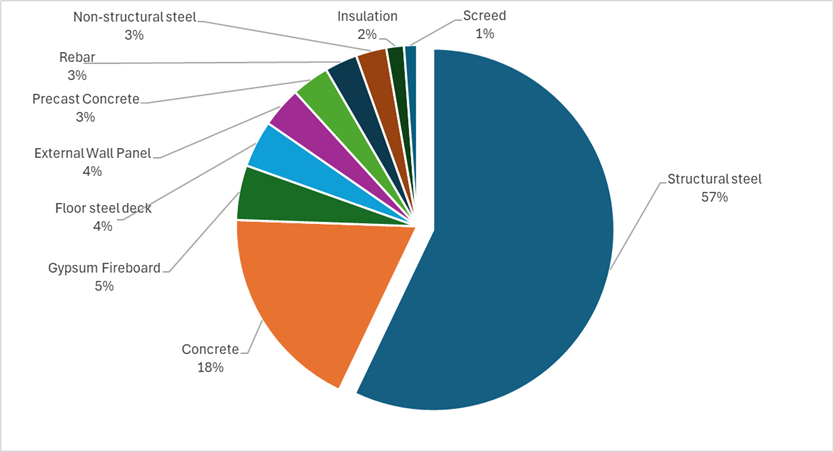

While no widely adapted DC baseline WLCA target exists as yet, one of the most progressive recommendation for a DC is enshrined in UK Net Zero Carbon Building Standard (NZCBS), in which a Core and Shell limit of 705 kgCO2e/m2 is envisaged for 2026. The following Pie chart is the breakdown of civil and architectural embodied Carbon for a typical DC in Europe. The result represents a two storey steel-framed building (GIA: 30,000m2). Remarkably 57.1% of the total CO2e footprint is attributed to structural steel. Alliance for Sustainable Building Products (ASBP) state that using reclaimed steel can offer up to 97% reduction in embodied Carbon when compared to virgin steel [4]. Hence in the context of the typical steel framed DC examined here, an overall reduction of up to 55.4% can potentially be achieved in the architectural and civil segments of WLCA via steel reclamation. Steel Reclamation alone therefore can simply bring a DC design (or refurbishment) inline with NZCBS guidelines, and accelerate tech sector’s decarbonisation.

Figure 5. Architectural & civil embodied CO2e breakdown of a typical steel-framed DC in Europe (excludes MEP). Structural steel typically accounts for about half the embodied Carbon of steel-framed structures and hence reclamation can have significant Carbon reduction benefits. ![]()

CONCLUSION

Structural steel is an obvious candidate for reclamation and reuse as opposed to the current, common practice of recycling by remelting. CO2 saving potential of reclaimed steel are reported to be up to 97% [4] as it eliminates the substantial extraction and production energy expenditures of virgin steel. In a typical European DC building examined here, 57.1% of overall architectural & civil embodied CO2e are attributed to steel. Increased structural steel reuse will help the construction industry be more resource efficient, reduce waste and lower embodied Carbon impacts. In doing so it will substitute steel imports and by default stimulate new business opportunities in the UK (and the EU).

In a relentless pursuit to source and secure clean power, the tech sector has been keenly focused on long term contracts for renewable energy and power purchase agreements (PPAs). The best practice guides continue to bring a sharper focus on embodied Carbon, circularity and Scope 3 emissions. Therefore looking at steel reclamation can promise big wins for overall project CO2e reduction, setting an example and pioneering a new age of low impact tech infrastructure development. The tech sector can now begin to appreciate the value of the old too.

References:

[1] image cautery of ancient origins, https://www.ancient-origins.net/ (accessed Jan 2025).

[2] Word Steel Association online data (2021), ‘Energy use in the steel industry Fact Sheet’. Available at https://bit.ly/4it8bkC (accessed Jan 2025).

[3] Brown, D., et al., ‘Structural steel reuse: Assessment, testing and design principles.’ SCI publication. The steel construction in 72 (2019).

[4] Belinda Smart, New Civil Engineer (2025), ‘Why is steel reuse uptake low despite proven benefits’. Available at https://bit.ly/4iOwmtz (accessed Jan 2025).

Latest Insights

View all insights

Blending Innovation and Regulation: The New Data Centre Design Recipe

10 Mar 2025

The Importance of Physical Security Risk Assessments During Site Selection

10 Mar 2025